How to choose equipment for a regular insulating glass factory

For ordinary insulating glass factories, choosing the right insulating glass equipment is a core link to ensure product quality, improve production efficiency and enhance market competitiveness. During the equipment selection process, it is necessary to ensure that the equipment is deeply compatible with the actual needs of the factory.

1. Production scale is the primary consideration factor:

For small and medium-sized factories that are in the start-up stage or have a small order volume, it is recommended to give priority to semi-automatic equipment. Take horizontal cleaning machines, horizontal laminating machines, semi-automatic aluminum bar bending machines and handheld gluing machines as examples. These types of equipment have low initial investment costs, relatively flexible operation, and can meet the production needs of small-batch and diversified orders.

For factories with stable orders and large production scales, fully automatic insulating glass production lines have more advantages. The fully automatic production line can achieve full-process automated operations such as glass sheet loading, cleaning and drying, aluminum frame assembly, molecular sieve filling, sheet bonding, and sealing with glue. Its hourly production capacity can reach tens to hundreds of square meters, significantly enhancing production efficiency and meeting the demands of large-scale order delivery.

In addition, the factory also needs to select equipment based on the type of products. If the main focus is on irregular-shaped and large-sized insulating glass, it is necessary to be equipped with equipment with customized processing capabilities. If the focus is on the production of high-end products such as Low-E glass and laminated insulating glass, equipment suitable for special processes needs to be selected, such as equipment with high-precision coated glass cleaning functions.

2.The quality of the core components of the equipment directly determines its stability and service life

In the glass cleaning process, the brush material of a high-quality cleaning machine should have good wear resistance and cleaning effect, and the transmission roller should have high-precision parallelism to ensure that the glass is cleaned thoroughly and without scratches. In the sealing process, the precision of the glue pump and the accuracy of the metering system of the glue sealer are of vital importance. High-precision gluing equipment can ensure the uniform application of butyl rubber and silicone rubber, forming a stable sealing layer and preventing problems such as air leakage and fogging in insulating glass.

In addition, the processing accuracy of the equipment is also a key indicator. Take the aluminum bar bending machine as an example. High-precision equipment can control the bending error of aluminum bars within a very small range, ensuring the precise size of the aluminum frame and a perfect match with the glass. The precise measurement of the molecular sieve filling machine can ensure uniform molecular sieve filling volume, effectively adsorb the internal moisture of insulating glass, and extend the service life of the product.

3. Attach importance to the levels of intelligence and automation

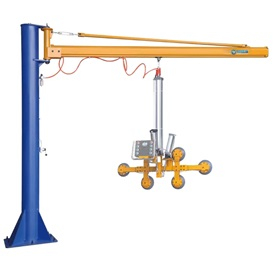

Intelligent equipment has become the development trend of the industry, and the production transformation it brings should not be underestimated. The insulating glass production line equipped with an intelligent control system can automatically complete parameter adjustments through preset programs, such as automatically setting the cleaning speed, gluing thickness, and laminating pressure according to the glass specifications, reducing manual intervention and operational errors. Meanwhile, intelligent devices can also collect production data in real time, such as output, energy consumption, and equipment operation status. Through data analysis, they can optimize the production process and enhance management efficiency. The automation function can further liberate human labor. For instance, the automatic sheet loading system can replace manual handling, reduce labor intensity and minimize safety hazards. The automatic identification system can quickly identify the size and type of glass, achieve automatic switching of equipment, and improve production flexibility.

4. Evaluate after-sales service and technical support

Perfect after-sales service is an important guarantee for the stable operation of equipment. When choosing a supplier, it is necessary to examine its after-sales response speed to ensure that technicians can arrive at the site promptly for repair when equipment malfunctions. Meanwhile, the supplier should provide comprehensive training services, including equipment operation, daily maintenance, and simple troubleshooting, to help factory operators quickly master the skills of using the equipment. Furthermore, the continuity of technical support is also of crucial importance. With the continuous development of industry technology, suppliers need to have the ability to upgrade equipment, providing services such as software updates and hardware upgrades for factories, so that the equipment always maintains technological advancement and ADAPTS to market changes.

5. Conduct a comprehensive analysis of cost-effectiveness

The cost of equipment procurement is a direct expenditure, but the long-term operating cost should not be ignored either. Although energy-saving equipment has a relatively high initial purchase price, it adopts advanced energy-saving technologies such as high-efficiency motors and intelligent temperature control systems, which can reduce the energy consumption of equipment operation. Long-term use can significantly save production costs. The durability and ease of maintenance of equipment also affect the overall cost. Equipment with reliable quality and reasonable structural design not only has a low failure rate but also is easy to maintain, which can reduce downtime and maintenance costs. In addition, the depreciation period of equipment is also an important factor in cost analysis. Choosing equipment with a long service life can spread out the procurement cost and improve the return on investment of the equipment.

When choosing equipment, ordinary insulating glass factories need to conduct a comprehensive assessment from multiple aspects such as production requirements, performance and quality, degree of intelligence, after-sales service and cost-effectiveness, weigh the pros and cons, and select the equipment that best suits their own development, laying a solid foundation for the sustainable development of the factory.