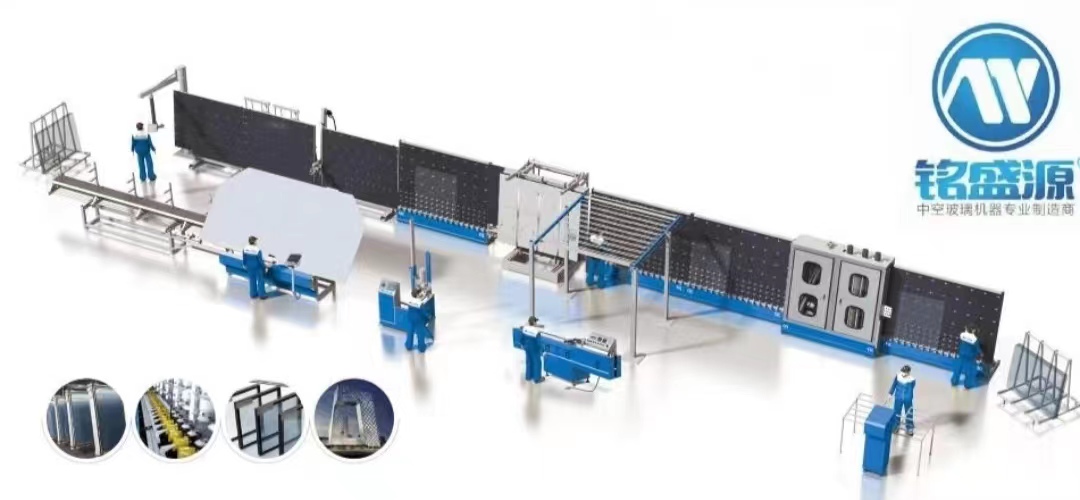

Shandong Mingshengyuan automatic insulating glass equipment performance

Automatic insulating glass equipment has a variety of excellent performance, the following are some main aspects:

1. Efficient production performance

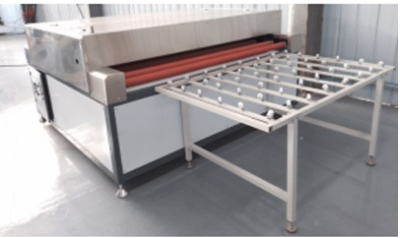

a. High degree of automation: the insulating glass production line can automatically complete multiple processes of insulating glass production, such as loading, cleaning, gluing, laminating, and pressing, reducing manual operation, improving production efficiency, and reducing labor costs.

b. Fast production speed: with high-speed motor, precise transmission device, etc., several pieces of glass can be processed per minute to meet the needs of large-scale production.

c. Strong continuous operation ability: equipped with a large capacity of raw material supply system and stable mechanical structure, can work continuously and stably for a long time to achieve 24-hour uninterrupted production.

2. High precision machining performance

a. High dimensional accuracy: Using high-precision sensors and control systems, the glass cutting size error can be controlled within ±0.5mm to ensure that the glass size meets the standard.

b. High position accuracy: the operation of the insulating glass gluing machine can be accurate to the millimeter level, to ensure that the glue layer is uniform, the glass is closely fitted, and to avoid dislocation and unequal gaps.

c. Accurate thickness control: Through the pressure sensor and thickness detection device, the thickness of the insulating glass can be accurately controlled, and the deviation can be controlled within ±0.2mm.

3. Reliable quality performance

a. Good stability: the key parts are made of high-quality materials and advanced manufacturing processes, which have been strictly tested and inspected, and the equipment failure rate is low, which can reduce the production interruption and quality problems caused by equipment failure.

b. Perfect quality detection function: equipped with a variety of testing devices, such as glass thickness detector, rubber layer detector, etc., can detect product quality in real time, find and correct problems in time, and ensure product pass rate.

c. Complete protection functions: multiple safety protection devices, such as emergency stop button, light screen sensor, etc., can effectively protect the safety of operators and prevent safety accidents.

4. Multi-function integration performance

A. Can process a variety of types of glass: automatic insulating glass production line can process ordinary flat glass, coated glass, Low-E glass and other different types of insulating glass, to meet the diversified market demand.

b. With a variety of process functions: in addition to the basic insulating glass production functions, it can also integrate glass edging, drilling, tempering and other processes to achieve one-stop processing.

c. The intelligent control system has rich functions: it can realize parameter setting, production data recording and analysis, fault diagnosis and alarm and other functions, which is convenient for operators to carry out production management and quality control.

5. Energy saving and environmental protection performance

a. Energy-saving design: energy-saving motor, optimized circuit control system, etc., reduce energy consumption of equipment, compared with traditional equipment can save 20%-30%.

b. Environmentally friendly materials and processes: The use of environmentally friendly sealant, cleaning agents and other materials to reduce environmental pollution, while optimizing the production process, reduce waste and exhaust emissions.